Waste to energy

technology

Abir Holdings Inc is responsible for the deployment of technologies owned by Rok Venture Holdings LLC, a joint venture between world renowned Scientists and Business minds. We took on the challenge to make our planet cleaner, more efficient and technologically advanced by deploying impactul innovations.

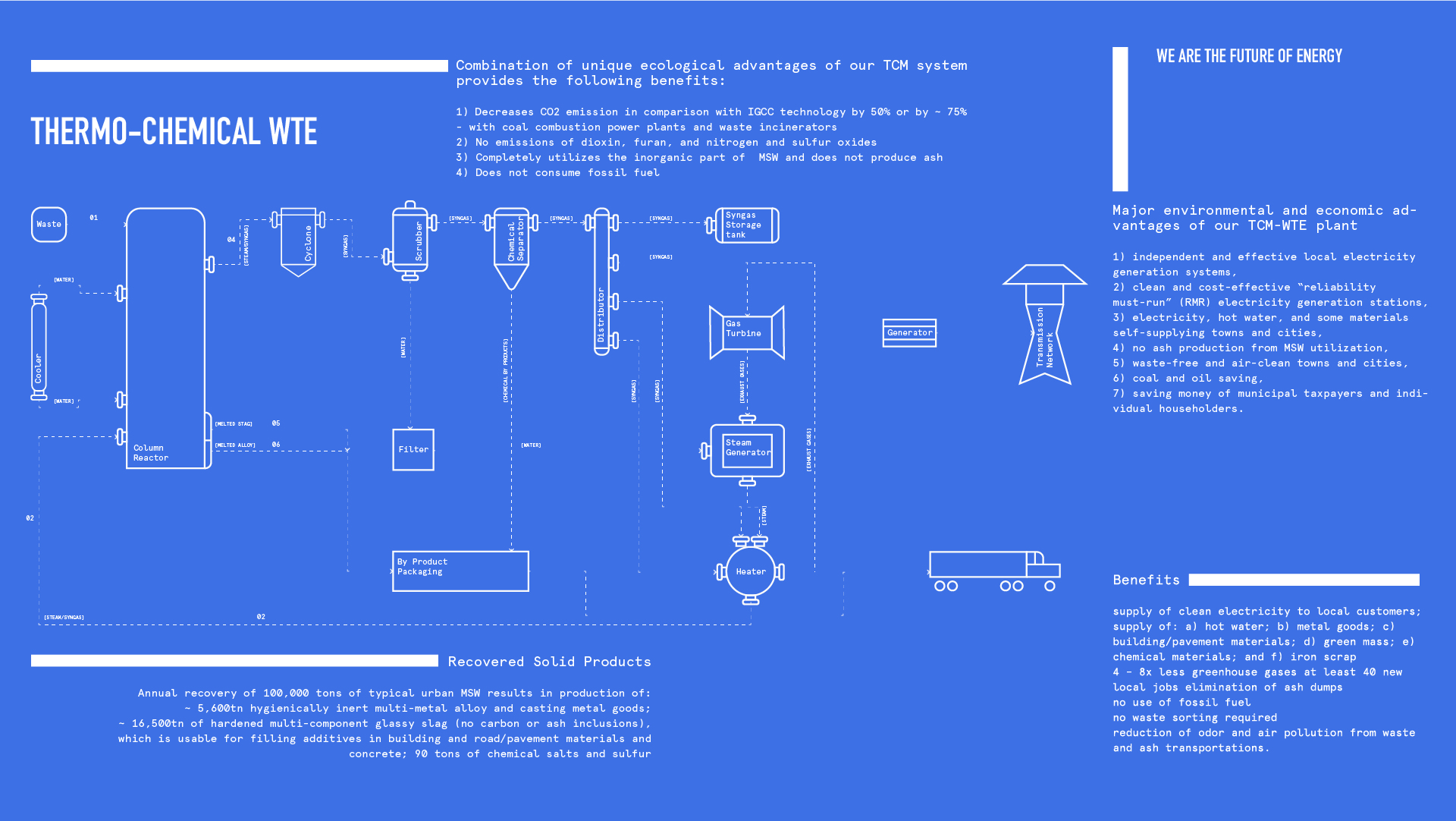

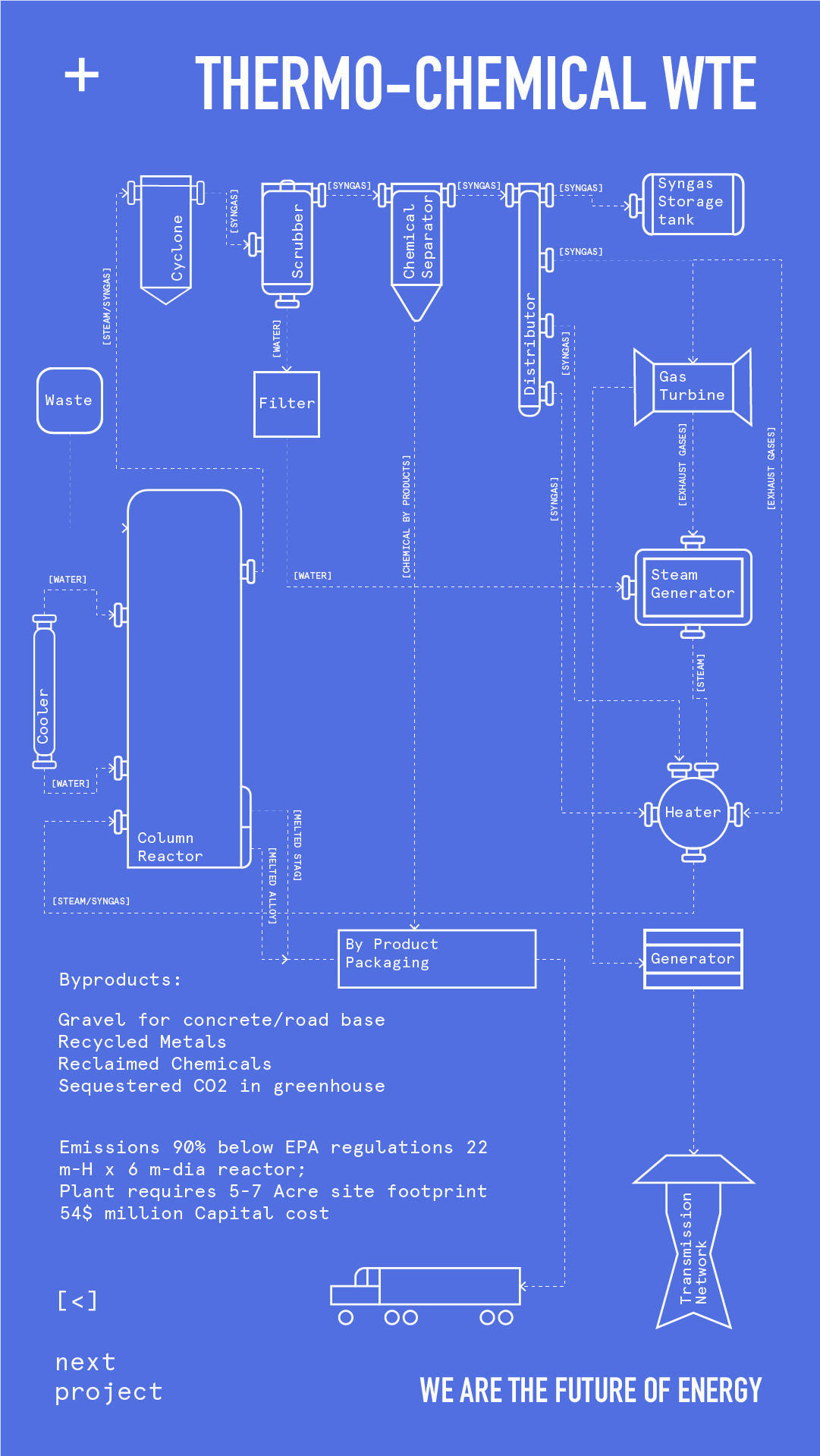

We created, tested and patented a highly profitable Thermo-Chemical Method (TCM) system

for treatment of municipal solid waste (MSW), along with commercial and industrial waste. Our

TCM and Gasification System is sustainable, inexpensive, cost-effective and efficient. The

Technology is free of pollution, ash or secondhand waste production. The intended system

makes for cost effective power production as well as the creation of useful byproducts from any

kind of raw material including hazardous waste.

Our mission is to enable Global Leaders to answer the most challenging question:

“What Should We Do With Our Waste?”